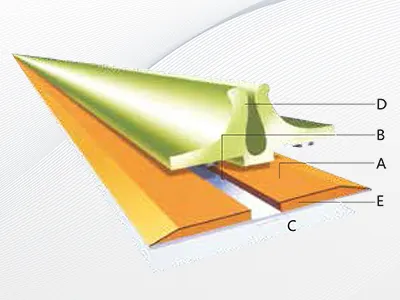

Our quick-mounting creasing matrices are essential components for die-cutting machines. They are used to create precise creases on paper, cardboard, plastic film, and other materials, facilitating subsequent folding and forming operations. Their quick-mounting design significantly improves production efficiency.

| Sheet Weight (g) | Sheet Thickness (mm) | Creasing Rule Height (mm) | Commonly used creasing rules | ||||||

| 23.50 | 23.40 | 23.30 | 23.20 | 23.10 | 23.00 | 23.24 | 22.9 | ||

| 200 | 0.28 | 0.3×1.0 | 0.4×1.0 | - | - | - | - | 0.5×1.0 | - |

| 250 | 0.35 | 0.3×1.2 | 0.4×1.2 | 0.5×1.2 | - | - | - | 0.5×1.2 | - |

| 300 | 0.42 | 0.3×1.3 | 0.4×1.3 | 0.5×1.4 | - | - | - | 0.5×1.4 | - |

| 350 | 0.50 | - | 0.4×1.4 | 0.5×1.5 | 0.6×1.5 | - | - | 0.5×1.5 | - |

| 400 | 0.56 | - | - | 0.5×1.6 | 0.6×1.6 | - | - | 0.5×1.6 | 0.8×1.6 |

| 450 | 0.63 | - | - | 0.5×1.7 | 0.6×1.7 | 0.7×1.7 | - | - | 0.8×1.7 |

| 500 | 0.70 | - | - | - | - | 0.7×1.7 | 0.8×1.7 | - | 0.8×1.7 |

Reverse bend creasing matrices are designed to create reverse creases (raised lines) on the material's surface. Unlike conventional creases (indentations), reverse creases are formed on the back of the material, resulting in a raised line on the front. This technique assists in achieving precise and crisp folds, particularly in applications requiring a firm and structured fold.

Calculations:

The following formulas are used for calculations:

Distance between cutting steel lines (d):

For paperboard: d = (paper thickness (g) x 1.5) + creasing width (c)

For corrugated cardboard: d = (paper thickness (g) x 2.0) + creasing width (c)

Steel rule height (h):

h = cutting die height (f) - (paper thickness (g) + base height (a))

Ideal for the printing and packaging industries, our pile turners perform a variety of functions, including dust removal, loosening, aligning, and flipping paper stacks. These machines are indispensable for improving efficiency in pre- and post-press processes.

| Model | HF-FZ1200 | HF-FZ1200A | HF-FZ1700ZL |

| Max. Pile Weight (pallet included) (kg) | 100 | 1400 | 2500 |

| Max. Sheet Size (mm) | 800×1200 | 800×1200 | 1200×1700 |

| Jaw Opening (mm) | Min. 680 Max. 1440 |

Min. 920 Max. 1920 |

Min. 920 Max. 1840 |

| Power (kW) | 8 | 8 | 16 |

| Power Supply | 3p380v AC50HZ | ||

| Max. Pressure | 16MPa | ||

| Noise Level | < 80 dB(A) | ||

| Temperature | 12℃ to 45℃ | ||

| Relative Humidity | < 50% non-condensing | ||

| Net Weight (kg) | 2800 | 3600 | 4200 |

| Dimensions (mm) | 2370×2090×1890 | 2900×2400×2200 | 2550×2590×2590v |

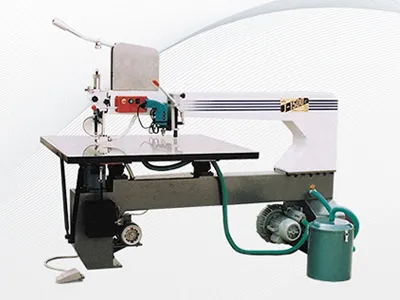

The J-1500 sawing machine is designed for creating precise saw cuts in die boards, ranging from quarter-size to extra-large formats. The lower chuck features an automatic saw blade clamping device for quick and efficient blade changes. The upper chuck position and worktable angle are easily adjustable for enhanced versatility. The extra-large worktable surface is mirror-finished and equipped with an air flotation system for effortless handling of large die boards. A powerful dust collection system keeps the work surface clean and the environment healthy.

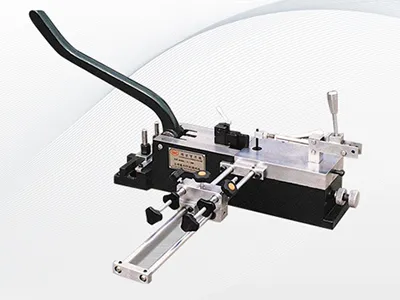

Engineered for bending steel, this machine rules to create the cutting edges of dies. Its innovative and practical design ensures ease of use and high precision. Equipped with 40 male and female dies (molds), it can bend steel rules into any complex shape.

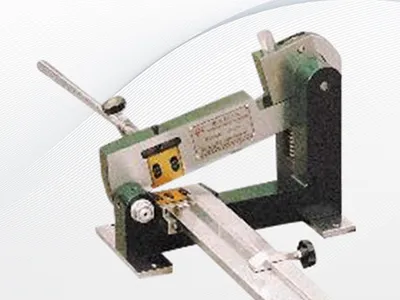

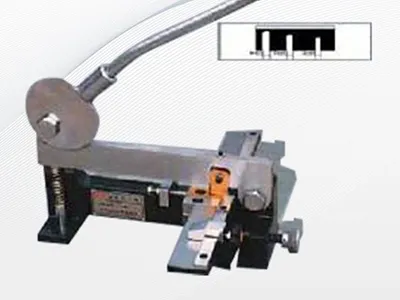

Designed for trimming and angle cutting, the QD-25M allows for easy conversion between cutting and corner cutting functions by simply changing the baffle. The cutting blade is made of tungsten steel with a hardened surface for exceptional durability. The standard model can cut steel rules up to 32mm high. Custom models are available for higher blades (40mm, 50mm, or more).

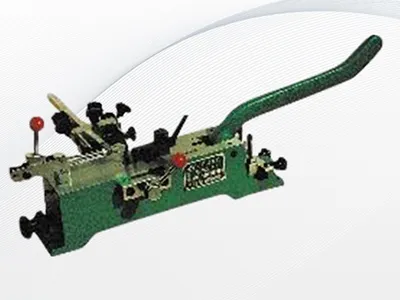

The CX-25B steel rule bender efficiently bends die cutting blades into complex shapes. With 35 sets of male and female molds and dual positioning systems, it ensures fast, accurate operation with minimal operator effort.

Similar in functionality to the CX-25B, the CX-5A steel rule bender offers rapid and convenient blade bending using 35 sets of male and female molds for producing complex shapes.

This versatile machine combines cutting and corner cutting functions. With interchangeable positioning bars, it easily switches functions to meet various production requirements.

After rule (blade) bending, the YK-06 steel rule notcher punches bridge holes with precision. Available in notch widths of 3 mm, 5 mm, or 6 mm, it ensures uniform notching for consistent blade quality.

Designed to punch notches along die cutting blades or crease lines at joint points, the CK-9 offers a fixed notch width of 9 mm and adjustable notch depths from 0 to 25 mm, maintaining efficiency without deforming the blade.

Used for the final cutting stage, the CJ-25 steel rule cutter features adjustable guides on both sides to deliver straight, smooth cuts. It supports a maximum blade height of 40 mm, reducing operator effort and ensuring a clean finish.

The GQ-3-8M precision steel rule notcher is designed for punching bridge holes at the junctions of die cutting blades and crease lines. Offering notch widths of 3 mm, 5 mm, or 8 mm, it utilizes tungsten steel notching blades with enhanced durability through surface hardening.

We provide a variety of die-cutting equipment for printing companies, packaging companies, manufacturing companies, and more. Our die-cutting equipment uses cutting-edge stable components from well-known international companies, such as frequency converters from Swiss ABB, programmable controllers and human-machine interfaces from Japanese Fuji, relays and circuit breakers from Japanese Omron, IDEC (Izumi), and Schneider, motors from German Siemens, paper conveying belts from Japanese NITTA, chains from German IWIS, bearings from Japanese NSK, and others. This ensures our equipment has higher accuracy (±0.1mm ~ ±0.075mm), and we provide comprehensive after-sales service.