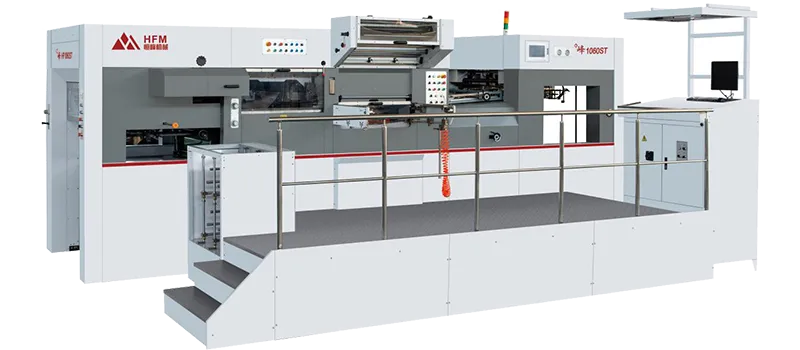

This model features a dual-station design and is equipped with a longitudinal 5-axis holographic foil feeding servo system, which increases the stamping speed and boosts productivity.

Equipped with a high-precision four-suction, five-feed feeder head, this system adapts to thin paper, paperboard, and corrugated cardboard, ensuring consistent feeding even at high speeds. A gantry-type pre-feed mechanism alternates between the main and auxiliary feed tables to enable continuous, non-stop production.

Utilizes a dual-purpose push-pull side lay system for stable sheet positioning at high speeds. The quickly adjustable feeding wheels further improve work efficiency. An optional vacuum feeding system can be added for enhanced stability when processing thin paper.

Features a steel plate micro-adjustment mechanism that facilitates rapid alignment of the bottom mold, thereby increasing production efficiency and ensuring precise die cutting.

Incorporates a deformation-resistant, heat-resistant cast iron honeycomb plate and a gap-free ball screw pressure adjustment system. With 20 independently controlled heating zones, the unit maintains an even and rapid temperature response to ensure optimal foil stamping and die cutting performance.

Employs a three-axis high-position foil feeding system with an extendable, retractable foil rack for quick foil replacement. A two-axis servo foil feeding system, complete with a tear detection system, ensures continuous and accurate foil delivery.

Features an external longitudinal roller collection system designed to facilitate efficient scrap recovery and reuse of aluminum foil.

Uses a brush and rear air-blowing system to maintain stable sheet alignment. It is equipped with an electric auxiliary collection system for continuous production and a pneumatic sampling function for real-time quality checks. An optional counting and marking (tab insertion) feature is available for enhanced operational efficiency.

An intelligent computing system automatically calculates skip-step schemes for different products to maximize aluminum foil savings and ensure consistent foil stamping quality.

To maintain optimal performance and longevity of your machine, we recommend using genuine HFM consumables. We offer a complete range of high-quality replacement parts: Stripping pin, sliding plate, lower pin locking block, rubber wheel, timing belt, brush wheel, gripper bar, movable gripper

We provide die-cutting and hot stamping solutions for printing, packaging, and manufacturing industries, ensuring precision and efficiency in every production process.

We provide a variety of die-cutting equipment for printing companies, packaging companies, manufacturing companies, and more. Our die-cutting equipment uses cutting-edge stable components from well-known international companies, such as frequency converters from Swiss ABB, programmable controllers and human-machine interfaces from Japanese Fuji, relays and circuit breakers from Japanese Omron, IDEC (Izumi), and Schneider, motors from German Siemens, paper conveying belts from Japanese NITTA, chains from German IWIS, bearings from Japanese NSK, and others. This ensures our equipment has higher accuracy (±0.1mm ~ ±0.075mm), and we provide comprehensive after-sales service.